ENEXIO Water Technologies has expanded its program of free-standing lamella separators by a new model in modular design.

Instead of building larger separators, individual smaller modules can be connected in series. This saves costs, reduces space requirements and allows for solutions that are custom-tailored to process requirements and local conditions.

Our largest free-standing units boast a sedimentation surface of up to 700 m2 despite having a footprint of just 35 m2. Volume flows between 5 m3/h and 180,000 cubic meters per hour can be achieved.

All free-standing models, either round SKR or square SKT, can optionally be supplied with one or more flocculation tanks, agitator mechanisms and rabble rake fittings, along with all necessary peripherals.

Process

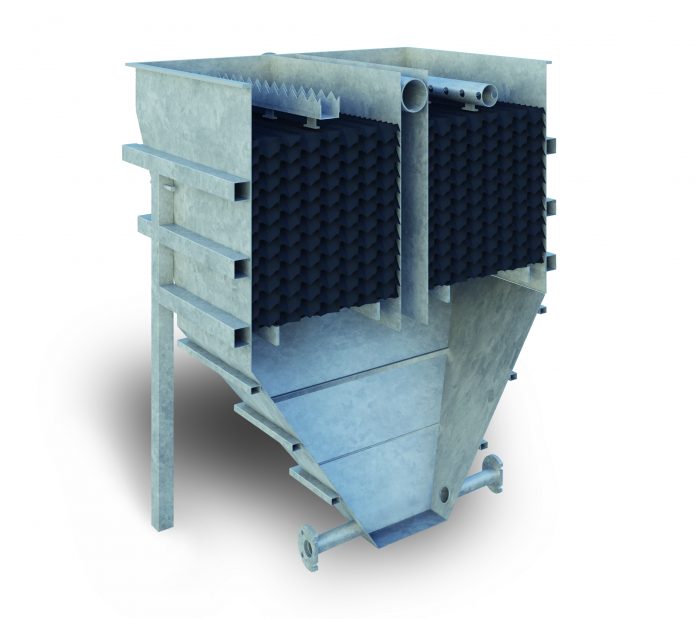

The inlet of the water is into the tank on one or two (opposite) sides. There the stream calms, flows downward and rises again through the lamella packs. In the separation section, the solids are separated and slide downward on the slanted surfaces of the TUBEdek lamellas.

There, in the thickening and storage zone, they accumulate and thicken further. The clear phase flows from the separating section upward and is collected above the clear water zone in the drainage channels. The separated sludge is removed from the sump of the thickening zone. This needs to be done at regular intervals.

Higher separation outputs thanks to TUBEdek parallel plate separators

The heart of it is inside the tank: our TUBEdek lamellas. The great number of equally spaced sedimentation levels of the lamella separators ensure a reliable separation process and provide the system with its high hydraulic capacity. As with plates, the sedimentation levels in the TUBEdek are parallel; the chevron-shaped channels have the same channel width and channel sizes as other channel shapes, e.g. hexagonal, but a significantly shorter sedimentation path. Furthermore, the channels support sludge removal.

The robust lamella packs guarantee a long service life.

Free-standing ENEXIO separators allow cost reductions

In comparison to conventional sedimentation tanks, the free-standing separator requires up to 90% less installation space. This and lighter, smaller foundations as well as low transport and installation expenses – installation can be done with a fork lift or crane – result in substantial cost savings. Sludge drainage is done by hydrostatic pressure, so pump energy is not required.

Our high-performance separators always work without flocculants or flocculation aids. An application-specific flocculation device plus peripherals can be integrated optionally.

Our separators consume negligible amounts of energy; maintenance effort and expenses are minimal.

Process advantages

In the free-standing ENEXIO separators, volumes and surface are ideally matched. The design offers an optimal balance between the separation and the thickening section in the container. Variable plate distances allow you to process dense or voluminous feed sludges and even abrasive solid particles. The design prevents any surface turbulences.

Thanks to the modular design, your system can be flexibly adapted. The SKT separators can be integrated into any system. Expansions by new modules are possible at any time. Thanks to the simple set-up and dismantling, process changes can be quickly implemented or temporary arrangements set up.

Optionally available

• Effective insulation against heat losses

• Covers to reduce the emission of harmful vapors and minimize evaporative losses

• Special materials and coatings

• Sludge level monitoring

Areas of application

• Raw water and backwash water treatment

• Primary and secondary sedimentation

• Sludge thickening

• Industrial process water treatment

• Treatment of electroplating wastewater

• Metal wastewater containing hydroxide

• Gravel wash water

• Cleaning of wastewater from pressure filtration, disc filtration, cloth media filtration, sand filtration

• Cleaning in biological and chemical treatment processes

• Water circulation in the potato and vegetable industries

• Treatment of waters from flue gas scrubbing and flue gas desulfurization

• Separation of abrasive media

• and lots more

ENEXIO Water Technologies is an exhibitor at the IFAT 2018, Hall A1 – Booth 425 and at Gate 5, and is represented at the booth of German Water Partnership in Hall B2 – Booth 227/326.